- Home /

- Quality Control

Quality Control

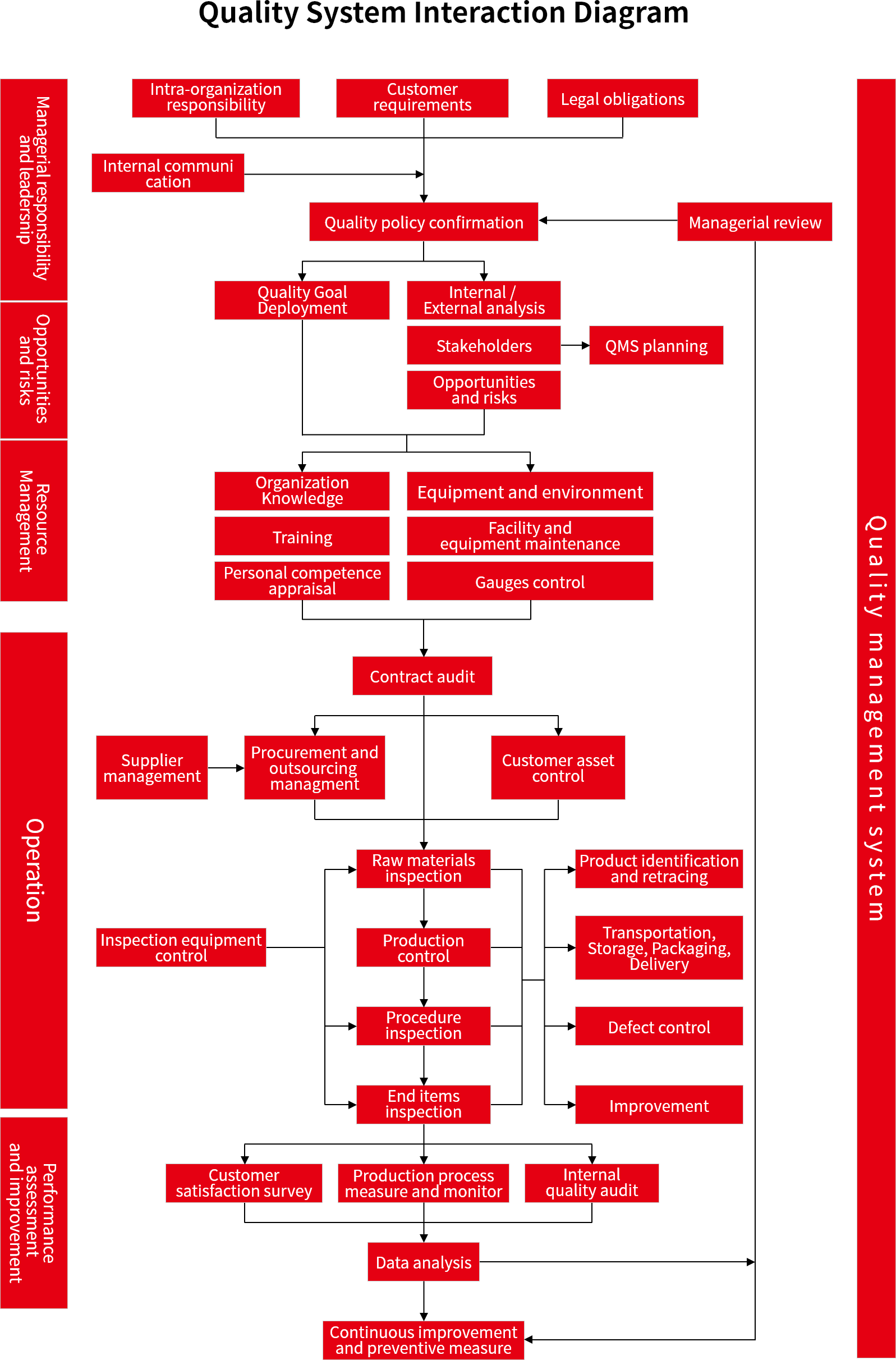

Quality Management System with Stakeholders in Mind

Yin-Ching keeps different stakeholders in mind, even in the quality control process. We include internal quality responsibility, customer requirements, and legal obligations in our holistic quality control process.

GOOD QUALITY, FAST DELIVERY

Our principle of customizing parts for automotive and motorcycle shock absobers is to provide high-quality parts through expeditious delivery. Our standardized holistic quality management system ensures that we can develop and machine parts in an efficient way.

Our quality management system conforms to ISO 9001: 2015. This means, from procurement of raw materials to final products, the production process is optimized through strict inspection and therefore achieves good quality and fast delivery.

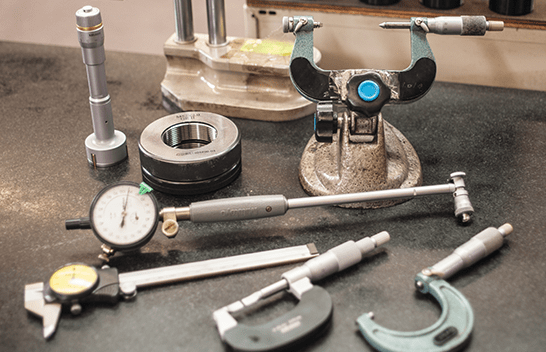

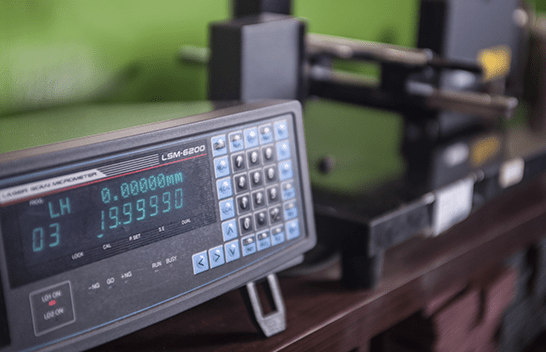

Quality Control Instruments

Yin-Ching uses multiple quality control measures in the machining process to inspect different machined parts for vehicles and motorcycles, such as damper tubes, piston rods and other customers’ orders.

| Machined Items | Measurements | Gauges |

|---|---|---|

| Raw material Quality Inspection | Dimensional measurement | Vernier caliper |

| Hardness test | Hardness tester | |

| CNC lathed Damper tubes and piston rods |

Dimensional measurement |

|

| Damper tubes machined through ID grinding | Dimensional measurement |

|

| Surface roughness test | Surface roughness meter | |

| Motorcycle piston rods machined through OD grinding | Dimensional measurement |

|

| Straightness |

|

|

| measurement |

|

|

| Heat treated damper tubes and piston rods |

Dimensional measurement |

|

| Surface roughness test | Surface roughness meter | |

| Hardness test | Hardness tester |

Service Info.

+886-4-8611686

No. 115-6, Tianzhong Rd. , Xihu Township, Changhua County 514, Taiwan